The Structure of Threads for Lace

The structure of thread deserves more attention than it has received.

Needle lacemakers, tatters and crocheters may have problems with the thread curling back on itself. They need to stop and let the lace or shuttle dangle and turn so that the thread resumes its normal twist.

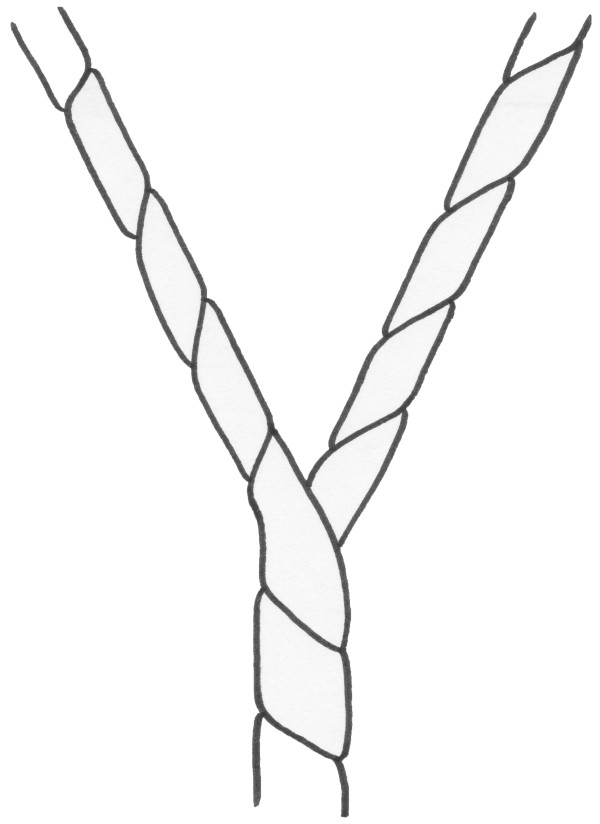

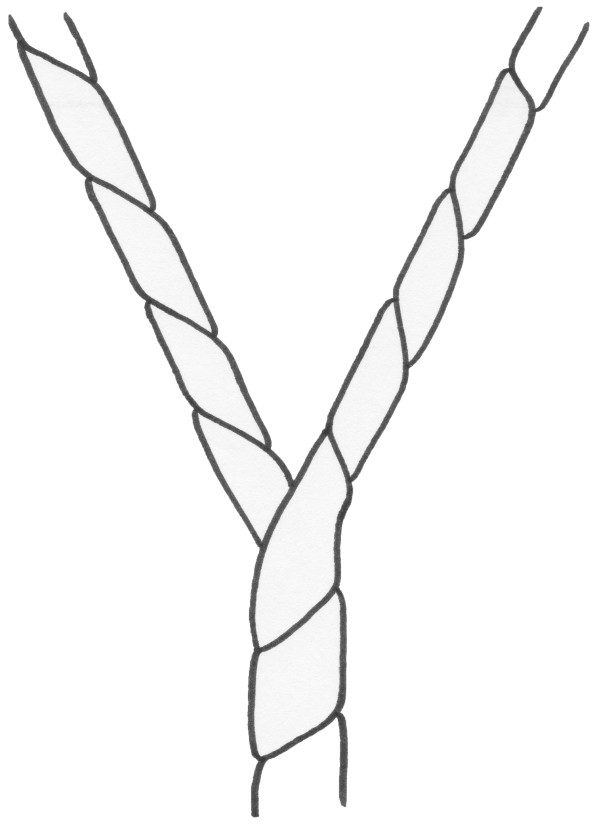

My interest began when I found that the early Irish crochet lace in my collection was worked in S-finished thread as shown at (A), whereas later items were made with Z-finished thread shown at (B). The old bobbin and needle laces were made with S-finished thread and today bobbin lacemakers are advised to use S-finished thread. Most threads used for bobbin lace today are Z-finished. Some S-finished threads for lace available in 2010 are listed on p. 6.

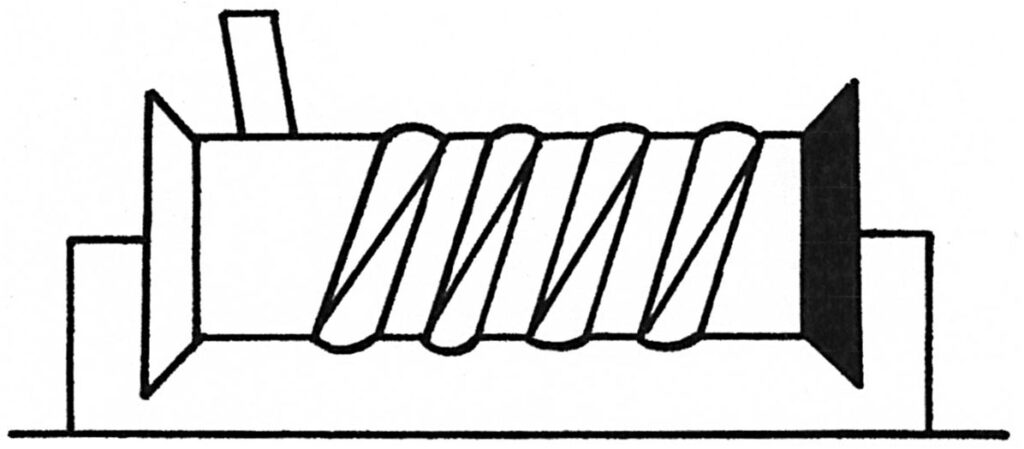

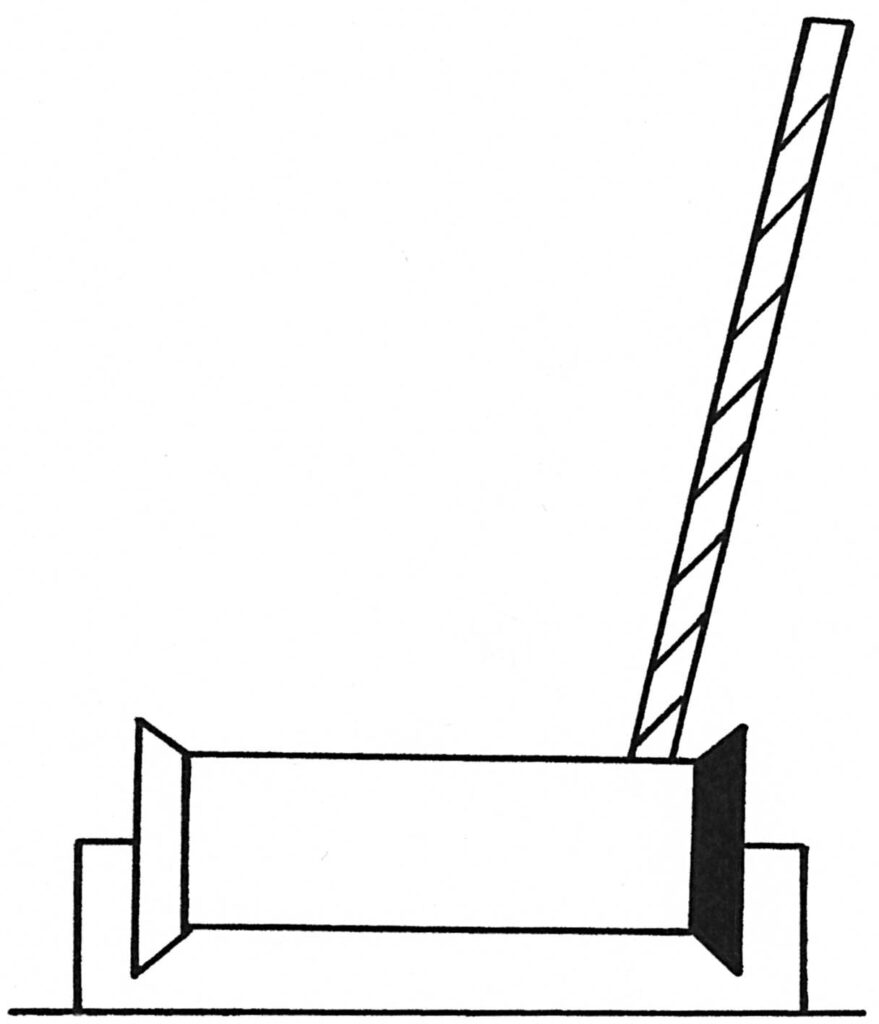

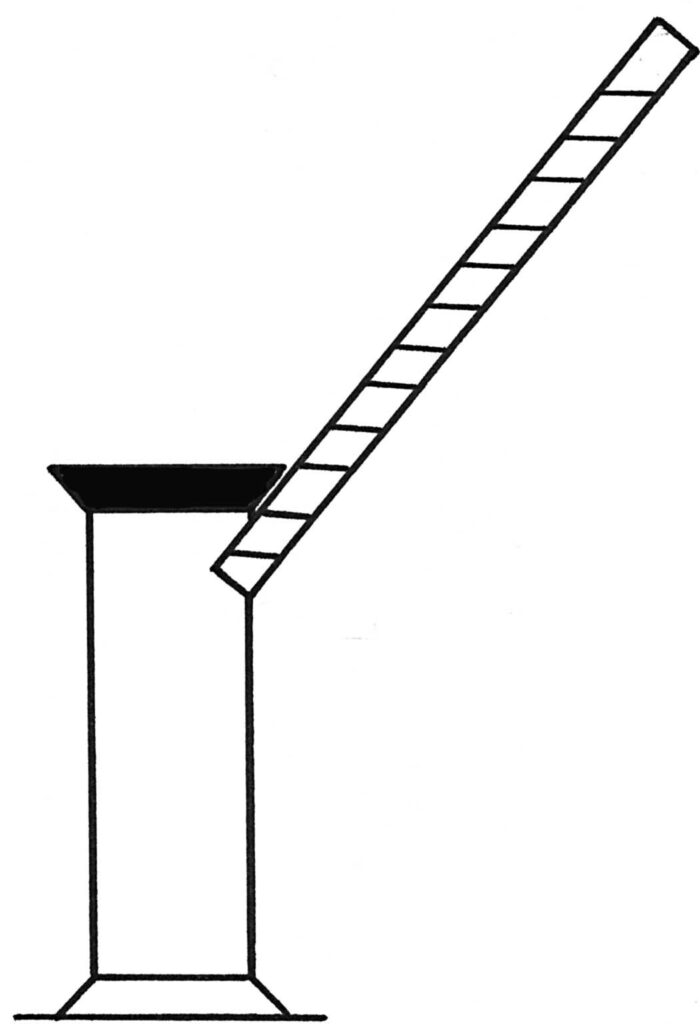

Few people realize that the amount of twist may change when the thread is taken from the ball, reel or spool as shown at (C) to (F). The thread around the reel on the spindle at (C), has 8 twists. Where it is rolled off the side as in (D), there is no change and the ribbon still has 8 twists.

However, when the spool is removed from the spindle and placed upright so that the thread runs anticlockwise around the cylinder and the thread is removed from the top in a clockwise direction as shown in (E) it will have four more twists, a total of twelve as in (F). Such thread will curl up on itself as in (G). Another possibility when the spool is inverted is shown in other diagrams in the book.

Other changes in the amount of twist may also occur in the process of lacemaking. For example, with the basic movements of cross and twist in bobbin lace and wrapping the thread around the crochet hook. There are personal variations in the ways of working too. One lace maker may find a certain thread produces good lace easily, but another may find it hard to use and produce poorer lace.

When I crocheted samples with five threads of similar thickness but different structures, there were few obvious differences so long as I used short lengths of thread and did not let the amount of twist change.

Dr. Philip Sykas of the Metropolitan University of Manchester wrote about a change from S-finish to Z-finish in sewing thread, about the end of the 1800s. The introduction of Z-finished threads for lacemaking may have followed this change in the much larger market for sewing thread.